Theme: Green Chemistry and Technologies: Advancing Towards a Safer and Sustainable Future

Euro Green Chemistry 2019

Organizing Committee cordially invites participants from all over the world to attend 10th World Congress on Green Chemistry and Technology, scheduled during July 10-11, 2019 at Paris, France mainly focused on the theme “Green Chemistry and Technologies: Advancing Toward a Safer and Sustainable Futureâ€.

Green Chemistry Congress aims to bring together the prominent researchers academic scientists, and research scholars to exchange and share their experiences on all aspects of Green Chemistry. It is also an interdisciplinary platform for researchers, practitioners and educators to present and discuss the most recent advances, trends, and concerns as well as practical challenges and solutions adopted in the fields of Green Chemistry.

10th World Congress on Green Chemistry and Technology will focus on many interesting scientific sessions and covers all frontier topics in Green Chemistry which includes Principles in Green Chemistry, Green Catalysis, Green Materials, Green Synthesis and Designing, Greener Bioprocesses, Green Chemistry applications in industries, Green energy, Waste Valorization techniques, Environmental Chemistry aspects, Green Economy, Sustainable flow chemistry, Green Engineering & Manufacturing, Green Polymers, Green Chemistry applications in different industries, Green Catalyst & Reagents and many more. In the coming years Green Chemistry is known as a specific field of science and technology. The focus is mainly on minimizing the hazards and maximizing the efficiency of any chemical choice. The conference also includes Keynote speeches by prominent personalities from around the globe in addition to both oral and poster presentations.

On behalf of Green chemistry 2019, Organizing Committee is glad to invite contributions from the enthusiastic academicians, scientists to organize International Symposiums/Workshops that are both empirical and conceptual in exploring new dimensions of green chemistry challenges towards achieving the solutions.

Why to attend???

- Meet experts and influencers face to face

- Conferences provide a great opportunity to network where most people can help each other uncover ideas and spark inspiration.

- Encounter new vendors and suppliers

- Attending a conference allows you to grow and challenge yourself

- Position Your Company as a Champion

- Network with leaders and influencers from the scientific, academic and R&D communities

Target Audience:

Directors, Presidents, CEO’s from companies, Business Intelligence Experts, Biofuels Plant Engineers, Recycling Specialists, Regulatory Specialists, Industrial experts, Scientists, Vice Presidents, Manufacturers, Research Associates, Brand Marketers, Advertising Agency Executives, Professors and Students from Academia.

Track 1: Biomass and its Conversion

Biomass is fuel that is developed from organic materials, a renewable and sustainable source of energy used to create electricity or different forms of power. Biomass is a renewable source of fuel to produce energy since waste residues will always be – in terms of mill residuals, forest resources and scrap wood; and forests will always have trees, and we will always have crops and the residual biological material from those crops. Biomass offers noteworthy environmental and consumer benefits, protecting air quality, and contributing the most dependable renewable energy source. Biomass energy has the potential to moderate greenhouse warming through the provision of energy from CO2-neutral feed stocks. Biomass does not add carbon dioxide to the atmosphere as it absorbs the same quantity of carbon in growing as it releases when it is consumed as a fuel. Biomass is a significant source of energy and the most important fuel worldwide after coal, oil and natural gas. Biomass conversion is mainly of two types – thermal related process and biological related process. Biomass could become an important part of future sustainable energy supplies. Many conversion types take into account the different feedstock going in due to the wide range of feedstock and the end product – heat, power, fuel, chemicals, and materials. Conversion technologies include biochemical conversion, Thermochemical conversion, pyrolysis, thermal degradation, anaerobic digestion, trans-esterification. Researchers, companies and the government are finding ways to convert biomass in a cost effective and efficient process.

Track 2: Cleaner production and Green Nanotechnologies

Green nanotechnology is the study of nanotechnology that can benefit the environment, such as by using less energy during the manufacturing process, the ability to recycle products after use, and using eco-friendly materials. Green nanotechnologies could be expected to assist in cleaning water via novel filtration techniques and the ability to decontaminate dirty water; solving efficiency disputes so as to increase the use of renewable energy; for waste management and environmental remediation. Green nanotechnology has its applications in green manufacturing, water treatment, renewable energy, environmental remediation and waste management. Green nanotechnology applications involves a clean production process, such as synthesizing nanoparticles with sunlight, the recycling of industrial waste products into nanomaterials, such as turning diesel soot into carbon nanotubes. Nanomaterials production in the areas of solar cells, biofuels and fuel cells. Cleaner Production is considered as a tool to reach sustainable development through the continuous application of an integrated preventative environmental strategy to processes, products and services so as to reduce risks to humans and the environment. Nanotechnologies will have a major impact on developing 'green' and 'clean' technologies with substantial environmental benefits.

Track 3: Environmental Chemistry and Pollution Control

Environmental chemistry is a branch of chemistry, comprising aspects related to organic chemistry, physical chemistry, analytical chemistry and inorganic chemistry, as well as more diverse areas, such as public health, biology, biochemistry, toxicology, and epidemiology. Environmental chemistry is the study of chemical processes occurring in the environment which are impacted by mankind's activities and the impacts may be felt through the presence of air pollutants or toxic substances from a chemical waste site, or through depletion of stratospheric ozone which may affect global warming. The present environmental problems lead to the remediation of environmental media, and to new, low energy, low emission, and sustainable processes. Environmental chemistry describes regarding the pollution of air, water, food and living organisms by toxic metals, soils, fossil fuels, pesticides and organic pollutants. Green chemistry highlights novel chemical reactions which are environmentally friendly.

Track 4: Green Analytical Techniques

Green analytical chemistry is a part of the sustainable development idea. Green analytical chemistry emphasis on environmentally friendly sample preparation techniques. Miniaturisation of analytical devices and shortening the time elapsing between performance analysis and reliable analytical results are important aspects of green analytical chemistry. Solvent less extraction techniques, the application of alternate solvents and assisted extractions are considered as main approaches complying with green analytical chemistry principles. Green analytical chemistry is a key part of green chemistry and an important trend in analytical chemistry in modern society. Green analytical chemistry is systematically discussed and then defined with seven principles. Important aspects of green analytical chemistry are discussed in detail with regard to the whole analytical process; i.e., from sample collection, sample preparation, to sample analysis, and some other related issues such as process analysis. Now a day, green analytical chemistry has driven attention to serve the sustainable development of the modern society. Green bioanalytical techniques aims to minimize or eliminate the hazardous waste associated with conventional bioanalytical methods. An efficient approach towards bioanalytical method development has a huge contribution towards the green analysis. The selection of organic constituents of the mobile phase, choice of type of sample extraction process, adoption of suitable separation procedure controls the green chemistry approach of the bioanalytical method. Supercritical fluid chromatography is one of the best techniques for green bioanalytical methods.

Track 5: Green Chemistry and Technology

The idea of green chemistry is study of new idea which developed in the business and regulatory society as a natural evolution of pollution preventive actions. In our exertions to improve crop protection, medicines, and commercial products where we are causing unplanned harm to our planet and humans. Green chemistry takes a stride further and builds new concepts for chemistry and engineering to design chemicals, chemical processes and products in a way that circumvents the production of toxic substances and waste generation. New catalytic reaction procedures continue to develop to advance the objectives of Green Chemistry, while methods such as photochemistry, microwave and ultrasonic synthesis has been broadly used, leading to remarkable results. Green Chemistry targets to eliminate generation of hazards at their design stage itself. Green chemistry decreases the pollution at its source by eliminating or lessening the risks of chemical feedstock’s, solvents, reagents, and products. Green chemistry is the design of processes and chemical products that lessening or reduces the generation of hazardous substances.

Track 6: Green Chemical Reactions

Reactions play the most major role in synthesis. Green Chemistry appeals for the development of new chemical reactivity’s and reaction conditions that can potentially provide benefits for chemical syntheses in empathies of resource and energy efficiency, operational ease, product selectivity, and health and environmental safety. Some of green reaction methods include atom economy where the reaction seeks to maximize the incorporation of the starting materials into the final product of any given reaction; direct conversion of C–H bonds where transformation of the C–H bonds of organic molecules into desired structures without extra chemical conversions represents another class of major desirable reactions; synthesis without protections where organic synthesis extensively utilizes protection–deprotection of functional groups, which increases the number of steps in synthesizing the desired compounds but green chemistry is needed to perform organic synthesis without protection and deprotection; flow reactors where importance to greener syntheses is the development of tandem and cascade reaction processes that incorporate as many reactions as possible to give the final product in single operation. In biocatalysis where the potential effectiveness of various catalysts such as enzymes, whole cells, and catalytic antibodies for organic synthesis has become more recognized.

Track 7: Green Catalysis and Biocatalysis

The key objective of green chemistry is waste minimization. A sustainable process is the one that optimizes the use of resources, while still leaving sufficient resources for future generations. Catalysis is an important tool in both the cases. Catalysis is the key to sustainability. A catalyst is a substance that facilitates a chemical reaction. A catalyst is something that makes a reaction goes faster, without being consumed in the process. Catalysis is divided into three categories: homogeneous catalysis, heterogeneous catalysis, and biocatalysis. Although the catalysts and the process conditions in every category can be different but the principles of catalysis are the same. Biocatalysis is a special case, somewhere between homogeneous and heterogeneous catalysis. In most of the cases, the biocatalyst is an enzyme – a complex protein that catalyzes the reactions in living cells. Green Catalysis is a part of green chemistry but the most important and one of the urgently needed challenges facing engineers now is the design and use of environmentally benign catalysts.

Track 8: Green Chemical Engineering

The chemical industry and other related industries supply us with a huge variety of essential products to everyday living. However, the chemical industries have the potential to extremely damage our environment. In the last span of 10 years, the scientific community has witnessed a growing interest in environmental issues and the value for environmentally friendly energy generation and chemical processes. The combination of chemical engineering tools with the new research findings of green chemists, biologists, and environmental scientists has allowed for designing new processes for the manufacture of chemicals, fuels, and products with a reduced environmental footprint. The developed environmentally benign alternate technologies have been proven to be economically superior and function as well as or better than more toxic traditional options. The design and efficient use of environmentally benign chemical processes, including the development of processes that use clean solvents and renewable resources, biocatalysis, alternative reactors, and innovative environmental technologies for water treatment and pollution control.

Track 9: Green Energy & Renewable Resources

Green energy, at times called renewable or sustainable energy comes from natural sources like wind, water, and sunlight. It is more environmentally friendly than other types of energy and doesn’t contribute to climate change or global warming. Green energy is generally defined as the energy that comes from natural sources such as sunlight, rain, plants, wind, waves, algae and geothermal heat. These energy resources are renewable in nature. Renewable energy sources have lesser impact on the environment which produces pollutants such as greenhouse gases as by-product, causative to climate change. Improvements in renewable energy technologies have lowered the cost of solar panels, wind turbines and other sources of green energy. Research into renewable, non-polluting energy sources is progressing at such a fast pace. The most common types of green energy include solar power, wind power, wind power, geothermal energy, biomass, and biofuels.

Track 10: Green Engineering and Sustainable Designing

Green engineering approaches the design, commercialization of products and the use of processes and products in a manner that concurrently reduces the amount of pollution that is generated by a source, reduces exposures to potential hazards, and promotes sustainability as well as protecting human health without effecting the economic viability and efficiency. Fundamental Principles of green engineering comprises engineering processes and products use systems analysis, and assimilate environmental impact assessment tools; minimising the depletion of natural resources; assure that all energy and material inputs and outputs are safe and compassionate as much as possible; Create solutions further than current technologies to improve, innovate, and invent to achieve sustainability.

Track 11: Green Technologies in food production & food processing

Food is a vital component of life and human survival. Increasing population growth with the demands resulting from industrialization has made the need for sustainable food production and processing technologies equally more important. Green technology is defined as application of environmental science, green chemistry, environmental monitoring and electronic devices to monitor, model and save the natural environment and resources, and to reduce the negative effects of human involvement. Key drivers of green technologies in food production & food processing of the evolution in the food supply chain includes in-depth description of food production, and processing use of life cycle assessment tool; approaches to improve food production practices; sustainable food processing approaches; emerging analytical techniques for sustainable research and development; challenges associated with the use of agricultural resources to grow biofuels and bio-based products; technologies to reduce the generation of process-induced toxins; factors that influence consumer perceptions about some of the current and emerging agri-food technologies.

Track 12: Green Polymers and Polymer composites

Green polymers are those which are produced using green or sustainable chemistry. Green chemistry relates to the design of chemical processes and products that reduce the use or generation of substances hazardous to humans, animals, plants, and the environment. Green chemistry strives to reduce and prevent pollution at its source. Natural polymers are usually green. In the production of polymers, green principles includes a high content of raw material in the product, a clean (no-waste) production process, No use of additional substances such as organic solvents, High energy efficiency in manufacturing, Use of renewable resources and renewable energy, Absence of health and environmental hazards, High safety standards, Low carbon footprint and Controlled product lifecycles with effective waste recycling.

Track 13: Green Manufacturing and Processes

Green manufacturing is the renewal of production processes and the establishing of environmentally-friendly operations within the manufacturing field. Greening of the manufacturing process, in which workers use fewer natural resources, reduce pollution and waste, recycle and reuse materials, and moderate emissions in their processes. The term green manufacturing can be observed in two ways that is the manufacturing of green products, particularly which are used in renewable energy systems and clean technology, and the greening of manufacturing reduces pollution and waste by minimizing natural resource use, recycling and reusing what was considered waste, and reducing emissions. Applications of green manufacturing includes lean manufacturing where attention paid to waste generated along the way and energy reduction in streamlined logistics; Materials reuse, recycling; Green plastics which are biodegradable; Product design; solvent less technologies; electronics; Automobile design and manufacture.

Track 14: Green Materials

Green materials are materials that are renewable in nature. Materials such as clay, sand and stone are green materials. Plant materials like grasses, straw, wood and bamboo are also green materials. Plant materials that grow quickly are renewable in nature. Reclaimed materials are materials that can be reused in their existing form for new resolutions. Reclaimed materials are green that means they can be re-purposed and reused. Recyclable materials are materials that can change from being waste material to being reused through reprocessing or re-purposing. Green materials are defined as materials which are non-toxic, improve occupancy health, lower cost, and conserve energy and water use and waste products. Non-toxic materials are those that do not cause harm to the environment. Green materials are also materials that have low embedded energy in their harvesting or collection, production, transportation and use.

Track 15: Green Solvents

Solvents are supporting materials used in chemical synthesis. They are not an important part of the compounds undergoing reaction, yet they play an essential role in chemical production and synthesis. The invention of various interesting organic solvents has resulted in some notable advances in chemistry, the relic of such solvents has led to various environmental and health concerns. As part of Green Chemistry, various cleaner solvents have been evaluated as alternates. The growth of Green Chemistry redefines the role of a solvent as ideal solvent facilitates the mass transfer but does not dissolve. Additionally, a desirable green solvent should be natural, nontoxic, cheap, and readily available. Natural green solvents include water and carbon dioxide. Moreover to the two “natural green solvents”, various non-natural ones have also been intensively studied as green alternatives. The most widely studied ones are ionic liquids and another innovative discovery is the recently developed “switchable solvents”. Beside these solvents, other synthetic solvents such as fluorous and property-changing soluble polymer systems have been evaluated as potential green alternatives.

Track 16: Industrial Applications of Green Chemistry

Chemical industry encompasses major chemicals, reagents, solvents, catalysts and almost all types of organic reactions for synthesis of active pharmaceutical substances. Many chemicals and chemical processes tangled are hazardous, toxic and may show adverse effects on human health and environment. Industries can influence and advance the environmental performance with utilizing green chemistry. Green chemistry is being employed to develop innovative drug delivery methods that are more effective and less toxic. Green chemistry has grown from a small idea into a new approach to the scientifically based environmental protection. By means of green chemistry procedures, we can minimalize the waste of materials, maintain the atom economy and avoid the use of hazardous chemicals. Green chemistry is being employing in different industries like food & flavour industry, pharmaceutical industry, paper & pulp industry, polymer industry, sugar & distillery industries, textile and tannery industry considering the principles of green chemistry while designing the processes and choosing reagents.

Track 17: Life Cycle Assessment and Environmental Sustainability

Green Chemistry offers an apt structure for achieving sustainability through its 12 principles proposed by Anastas and Warner, but it also poses significant barriers of which major one is the lack of evidence of good environmental performance of proposed green chemical processes. This is the point where the thesis requires a need for Green Chemistry to incorporate quantitative tools to evaluate the greenness of new chemical processes, a Life Cycle Assessment (LCA) for both environmental and economic issues. LCA will be evaluated in dealing with Advanced Oxidation Processes for wastewater treatment. LCA as quantitative tool in the framework of Green Chemistry and pollution prevention, thus serving as a tool to assess the sustainability of new products, processes and technologies. LCA is an environmental management tool which identifies all resources used and wastes generated to all environmental compartments (air, water and soil) over the whole life cycle of a specific good or service. The LCA methodology comprises of four steps: goal and scope definition, inventory analysis, impact assessment and interpretation.

Track 18: Novel Activation Methods

Some Non-thermal Activation methods such as ultrasound, biotransformation, microwaves, or photocatalysis are a part of the green practices used for the creation of high added value molecules. Microwave-assisted heating under controlled conditions is valuable technology where the organic synthesis on solid phase. Sonochemistry is the application of ultrasound to chemical processes and reactions. Biotransformation is a favoured method for the control of the selectivity and is extensively used in green chemistry. This methodology adds to the development of chiral chemistry in aqueous medium. The activation by photocatalysis under visible light is another method used in chemistry. In recent years, asymmetric organocatalysis has been broadly studied as a corresponding technique of organometallic catalysis. This new method is very striking because it by-passes the use of heavy metals.

Track 19: Trends in Green Chemistry

Green Chemistry has established firm ground providing essential pattern criteria for the advancement of efficient chemical syntheses. The twelve principles of green chemistry have been recognized as elementary principles for future sustainable chemical industry and environmental protection. Future Trends in Green Chemistry includes Biocatalysis and biotransformations processes, new enzymes for organic synthesis, Hydrogen production, Green chemistry and agricultural technologies, Green flow chemistry, Green chemistry and organic solar cells, Combinatorial Green Chemistry, Green chemistry in sustainable development, Green Nano chemistry, Oxidation reagents and catalysts, Supramolecular Chemistry.

Track 20: Sustainable Flow Chemistry

Green chemistry and flow chemistry are ideal partners for accessing novel chemical areas and outline extremely economical efficient tools. Flow chemistry defines a general vary of chemical processes that occur in a very continuous flowing stream, conventionally happening in a reactor zone. The flow chemistry depends on the concept of pumping reagents using various reactors types to perform specific reactions. A rise in the greenness and sustainability of chemical processes can be realized by using continuous-flow reactors. The process can lead to achieving reactions conditions which lead to decrease in reaction time and waste generation, avoiding ultralow temperature conditions, increasing the overall atom economy, broadening the safety window and decreasing the overall energy consumption to name a few. Results show that continuous-flow technology can be developed to meet the requirements of industry and help in contributing to green and sustainable chemical production processes. For efficient use of flow technology, there are few challenges which need to be addressed such as understanding the transformation of batch processes to those of flow, understanding reaction kinetics within these reactors and implementation of scale-up procedures. In addition to that, the increase in demand for continuous flow technology and their promising results may help in the substantial development of eco-friendly and greener organic transformations.

Track 21: Ultrasound Technology in Green Chemistry

The applications of Ultrasound in green chemistry and environmental applications have an encouraging future. Compared to traditional strategies, ultra sonication brings environmental friendliness, value efficiency etc. Novel studies have been using ultrasound technology in environmental analysis, water treatment, sludge treatment, Air purification, Soil Remediation.

Track 22: Waste Valorization Techniques

Waste Valorization is the process of transforming waste from organic materials, food and agriculture waste, producing a great deal of methane in landfills, several processes are being developed to convert organic waste materials into something useful materials or products to produce energy, chemicals, or materials that can be used in industrial processes. Developing advanced waste valorisation techniques for the green production of chemicals, materials, and fuels through the advancement of green techniques. Valorization is necessarily a concept of recycling waste into more valuable industrial chemicals. Using entrenched Green Processing technologies such as flow technology, Sonochemistry, pyrolysis/gasification, solid state fermentation and microbial digestion are used to convert the types of waste into high-value chemicals such as bioplastics, organic acids, furans, essential oils and fuels such as biodiesel, bio-alcohols, syngas/biogas, biofuels from pyrolysis of oils with the purpose of minimizing waste disposal volumes and eventually protecting the environment.

Track 23: Wood Products and Green Chemistry

Green chemistry and technology for and from wood has developed various divergent industrial products, such as bio-sourced, flexible films, green wood adhesives and preservatives, foams, composite matrices, laminates, hard and flexible plastics, abrasive grinding discs, and many more. Green chemistry related to wood products and products derived from wood become a hard and vast task considering the ferment of ideas and work in this field going on now for quite a few years. In wood products , the green chemistry deals with the elimination of toxic aldehydes from wood panel adhesives, bio-sourced adhesives derived from wood or vegetable matter which are used for wood products, tannin-based foams, paper surface laminates, natural fibre composites using tannin matrices, and continuous high-pressure paper laminates, hard plastics based on tannin-furanic materials and some of their applications, bio-sourced wood preservatives and flexible bio-sourced tannin-furanic films.

Track 24: Green Economy

Green economy is the clean energy economy encompassing mainly of four sectors: renewable energy such as solar, wind, geothermal; green building and energy efficiency technology; energy-efficient infrastructure and transportation; and recycling and waste-to-energy. The green economy is not just about the ability to produce clean energy, but also technologies that permit cleaner production processes, as well as the growing market for products which consume less energy. The green economy have need of that economic development is decoupled from the use of resources and environmental deprivation. A green economy can only be accomplished through the commitment and actions of multiple sectors and stakeholders in society including government, business and individuals.

Track 25: Green Market

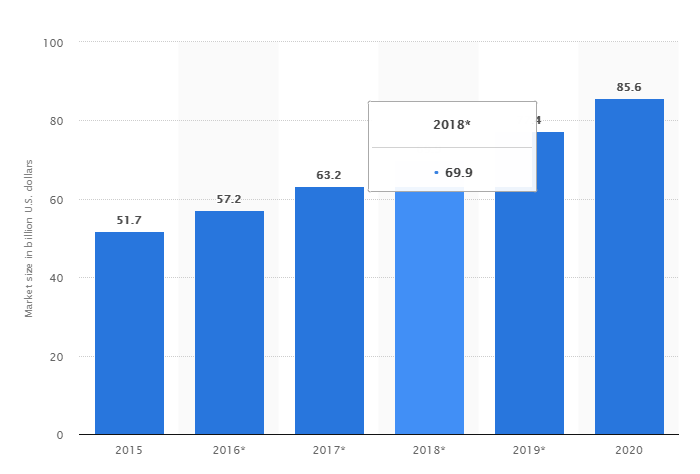

Green chemicals are renewable chemicals formed from bio-based feedstock. Green chemicals are produced primarily using raw materials, which uses natural resources while maintaining the environmental balance as well. The key bio-based raw materials used in the production of green chemicals are vegetable oils, animal fats, sugar and starch, and bio-ethanol. The government agencies have recognized the use of green chemicals will not only make sustainable and cleaner environment, but they can economically helpful in building social environment. Since chemicals are so pervasive in manufacturing, green chemistry has uses in many production areas, such as food processing, housing materials, textiles, transportation, pharmaceuticals, lubricants, resins, plastics. Drug manufacturers are entering the market with new ways to revolutionize the industry. An established pharmaceutical company, teamed up with a tech company Codexis to develop a greener method to manufacture sitagliptin drug, a treatment for type 2 diabetes. The new components used in the process are sustainable and biodegradable. In the present scenario Green chemistry is a big business, and it is expected to grow quickly. In 2015, the global market for green chemicals was almost $52 billion. By 2020, predictions estimate a rise to nearly $86 billion. Renewable alcohols have accounted for the greatest share about 41percent of the green chemistry marketplace. The green industry can enhance its growth by requesting and supporting government policies that strengthen it, including funding research, expanding education in the field and exploring foreign markets. The field of green chemistry grows; it must collect data about both progress and setbacks which would lead to more improved and safer products and processes.

Green chemicals, commonly known as bio based chemicals are produced from bio feedstock and thus, are renewable in nature. Green chemicals are much lesser harmful towards environment compared to petroleum based chemicals. The raw materials which are generally used in the production of green chemicals are bio-ethanol, sugar & starch, animal fats and vegetable oils. Green chemicals also consider biodegradation of the product after a certain period of time keeping the environment safe. Green chemicals find wide application across various end-use industries such as agriculture, construction, and automobile. Burgeoning growth of these industries coupled with the rising awareness towards environmental safety globally is expected to boost growth for the global green chemicals market.

Green chemicals accounted for 10% of the total chemical industry in 2015. Green chemicals are known for their environmental friendliness, providing a base for the sustainable chemical market. Since 2011, the industry is looking forward to finding the effective and economical expansion of green chemistry. Though over the years, applications in green chemicals have gained attention while the majority still remains at the laboratory or are at a pilot scale level. The growth in the green chemical industry is expected to be driven by bio-based chemicals in the long run. In 2015, over 50 million tonnes of bio-based chemicals were manufactured and this is anticipated to reach over 80 million tonnes by 2020. Application across various segments such as food processing, housing, textiles, transportation, hygiene, environment, and pharmaceuticals is anticipated to grow significantly over the next five years. By 2020, green chemicals market is projected to reach over $100 billion, with CAGR of 11%. Our reports provide a significant overview of the green chemical market, with respect to strategic analysis, regulatory framework, regional analysis, corporate portfolios and industry structure.

By 2020, the market for “green” chemistry is expected to reach $100 billion globally, with North America seeing an increase from $3 billion to over $20 billion during the same period. This growth, essential to the future of our planet, is a sign that the industry is engaged in much-needed change. Today, 8.3 percent of all deaths and 5.7 percent of the total burden of disease worldwide are related to chemical exposure.

With the increasing attention on sustainable chemistry, the public expects companies to ensure both new chemicals, and those already in a company’s portfolio, are more environmentally friendly. This pressure is especially intense on chemists because ‘green’ and ‘chemicals’ are not words that have typically gone together. In fact, the perception today is that the chemicals industry is not doing enough to promote safe chemistry, despite the range of vital and interesting work going on in this area.

This statistic displays the market size of the green chemistry industry worldwide in 2015, with forecasted figures for 2016 to 2020. The global renewable chemicals market size in 2015 was some 51.7 billion U.S. dollars, and it is forecasted that by 2020 it will be some 85.6 billion U.S. dollars.

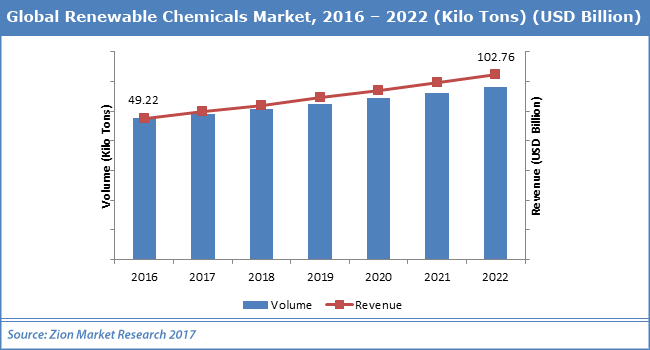

The global renewable chemicals market stood at US$ 49.22 billion in 2016. Witnessing a tremendous rise during the period from 2017 to 2022, the revenue in this market is expected to reach US$ 102.76 billion by the end of the forecast period. The main products available in renewable chemicals market are alcohols, ketones, biopolymers, platform chemicals, and organic acids. Among them, the demand for alcohol is relatively higher and the trend is anticipated to remain so over the next few years, notes the research report.

As per the global bio-based chemicals market forecast- The market for Bio-based chemical is anticipated to grow from $6474 million in 2016 to $23976 million by 2025, at a CAGR of 16.16% between 2017 and 2025. The base year considered for the study is 2016 and the forecast period is between 2017 and 2025. The concerns regarding the environment due to dangerous chemicals and depletion of fossil fuels are leading to the rise of the production of the bio-based chemicals. The Industrial chemical application is anticipated to dominate the global Biobased chemical market whereas the Agriculture application is anticipated to grow at a faster CAGR of 16.48% during the forecast period. The pharmaceutical industry is one of the major end-user industries for the consumption of bio-based chemicals. Food products are anticipated to hold a share of 20% by 2025. In terms of products, Biofuels have generated the highest revenue of $3690 million in 2016. On the other hand, Bioplastics are anticipated to grow at a faster CAGR of 16.43% during the forecast period. Biofuel market includes biodiesel, biogas and solid biomass. Biodiesel dominates the biofuel market by contributing $1437million in 2016. Biofuels are produced from organic material such as animal waste and plant materials. The bio-degradable market is the fastest growing segment in bioplastics market with a CAGR of 16.62% during the forecast period. Asia-Pacific is the largest market for the Biobased chemicals market, and the demand for Biobased chemicals in this region is anticipated to increase during the forecast period. Europe is the second-largest Biobased chemicals market, owing to the development of new value chains with bio-based feedstock, i.e. creation of biochemicals and biorefineries. North America is anticipated to grow at a faster CAGR of 17.03% during the forecast period. In Europe, Germany dominates the market followed by France, UK, and Italy. Asia Pacific is one of the largest producer and consumers of bio-chemicals. Currently, it accounts for 42.38% share of the total market. Availability of raw materials and the technological advancement is becoming the base of the market. The awareness of bio-based chemicals and its varied advantages are the major key factors for the development of the market.

The chemical industry is a key component of the French economy. Industry added value was estimated at €18.5 billion in 2017, more than 8% of the country’s manufacturing added value, ranking chemicals third behind the food and beverages and metallurgy. The chemical industry is a leading industrial exporter, first in front of aerospace. It accounts for more than 13% of total manufacturing exports and with a €8.6 billion trade surplus, chemicals ranks second only behind aerospace in its positive contribution to the national balance of trade.

Conference Highlights

- Biomass and its Conversion

- Cleaner production and Green Nanotechnologies

- Environmental Chemistry and Pollution Control

- Green Analytical Chemistry

- Green Chemistry and Technology

- Green Chemical Reactions

- Green Catalysis & Biocatalysis

- Green Chemical Engineering

- Green Energy & Renewable Resources

- Green Engineering and Sustainable Designing

- Green Technologies in food production & food Processing

- Green Manufacturing

- Green Polymers

- Green Materials

- Green Solvents : Properties and Applications

- Industrial Applications of Green Chemistry

- Life Cycle Assessment and Environmental Sustainability

- Novel Activation Methods

- Trends in Green Chemistry

- Sustainable Flow Chemistry

- Ultrasound Technology in Green Chemistry

- Waste Valorization Techniques

- Wood Products and Green Chemistry

- Green Economy

- Green Chemistry Market

To share your views and research, please click here to register for the Conference.

To Collaborate Scientific Professionals around the World

| Conference Date | July 10-11, 2019 | ||

| Sponsors & Exhibitors |

|

||

| Speaker Opportunity Closed | Day 1 | Day 2 | |

| Poster Opportunity Closed | Click Here to View | ||

Useful Links

Special Issues

All accepted abstracts will be published in respective Our International Journals.

Abstracts will be provided with Digital Object Identifier by